Lvl Beam Design Example Videos

FUTUREBUILD® LVL hySPAN®

hySPAN® laminated veneer lumber (LVL) is easy to work with using traditional building tools and is clearly branded for easy identification and your guarantee of quality. hySPAN is suitable for all structural applications in residential, commercial, industrial and rural buildings subject to design verification. hySPAN is not intended to support brickwork or other heavy masonry products.

Features & Benefits

- Straight, true, strong, lightweight and dimensionally stable

- Veneers are bonded together using type 'A' (marine) bond, known for long-term durability in structural applications

- Readily available and stocked H1.2 treated using a glue line and surface spray treatment to the requirements of NZS 3640

- Untreated and H3.1 LOSP treated product available made to order subject to minimum volumes and lead times, Contact us for further information

- Each piece is branded for ease of identification

- Stringent quality control – EWPAA certified

- Manufactured from sustainably-grown NZ plantation pine

- Available FSC® CoC Certified on request (Certificate Number: SCS-COC-001319)

- Residential Span Tables available - refer brochures below

- Supported by technical support and software from Futurebuild LVL

- designIT® software suite available

- computeIT® software suite available for specific engineering design

Compliance

Solid Futurebuild LVL products are manufactured in accordance with AS/NZS 4357, Structural Laminated Veneer Lumber. Characteristic Properties are determined in accordance with AS/NZS 4063.2:2010 and so comply with the provisions of the New Zealand Building Code through clause 2.3 for engineering design in accordance with NZS3603:1993 Timber Structures Standard.

Futurebuild LVL is committed to manufacturing innovative engineered building products. For quality assurance the Futurebuild range is manufactured with independent audit processes and product certification.

All Futurebuild LVL products are manufactured using a type 'A' bond with less than 0.5mg/L formaldehyde emissions from the final product (equivalent to E0).

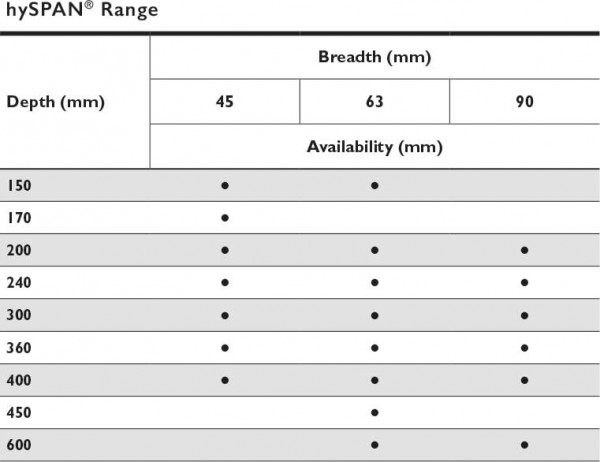

Range

- Available in 600mm increments from 2.4m to 13.2m

Software

Photo Gallery

Brochure

designIT for Commercial Floors Installation Guide

This guide provides a variety of details specific to the use of Futurebuild LVL floor systems for commercial, industrial and other heavily loaded floors. designIT® for Commercial Floors is a software tool for all building practitioners designing with the Futurebuild LVL range and other selected materials. It enables a wide range of commercial and industrial floor solutions to be developed in a simple and powerful application.

Technical Note

![]()

Futurebuild LVL Trouble with Substitutes

Think hard and check before substituting one building product for another. Get it wrong and you could be creating quality issues and have trouble getting a Code Compliance Certificate.

![]()

![]()

Sds

Product Technical Statement

Case Studies

Cad

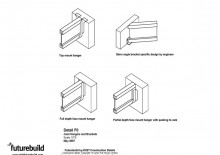

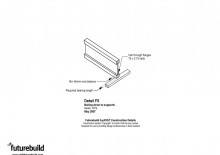

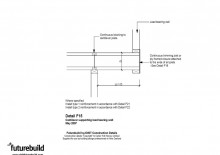

HYJ001 (F0)

Joist hangers and brackets (Detail F0)

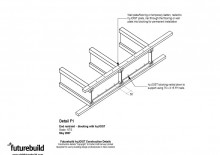

HYJ002 (F1)

End restraint- blocking with hyJoist (Detail F1)

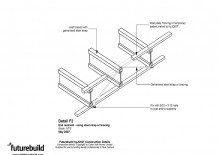

HYJ003 (F2)

End restraint- using steel strap or bracing (Detail F2)

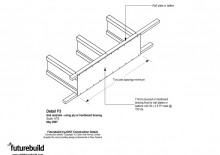

HYJ004 (F3)

End restraint - using ply or hardboard bracing (Detail F3)

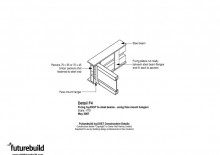

HYJ005 (F4)

Fixing hyJOIST to steel beams - using face mount hangers (Detail F4)

HYJ006 (F5)

Nailing down to supports (Detail F5)

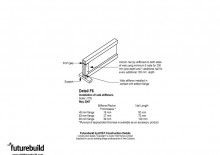

HYJ007 (F6)

Installation of web stiffeners (Detail F6)

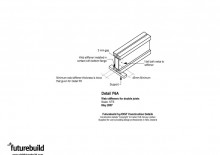

HYJ008 (F6A)

Web stiffeners for double joists (Detail F6A)

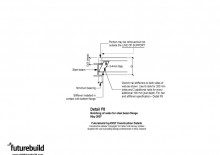

HYJ009 (F7)

Notching of flanges at end supports (Detail F7)

HYJ010 (F8)

Notching of webs for steel beam flange (Detail F8)

HYJ011 (F9)

Tie-down to internal bracing wall (Detail F9)

HYJ012 (F10)

hyJOIST/hyJOIST connection (Detail F10)

HYJ013 (F11)

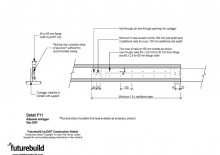

Adjacent outrigger (Detail F11)

HYJ014 (F12)

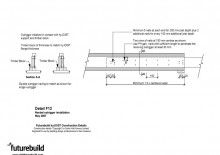

Nested outrigger installation (Detail F12)

HYJ015 (F13)

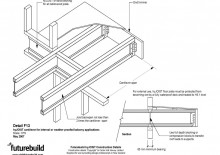

hyJOIST cantilever for internal or weather-proofed balcony applications (Detail 13)

HYJ016 (F14)

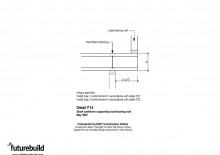

Short cantilever supporting load-bearing wall (Detail F14)

HYJ017 (F15)

Cantilever supporting load-bearing wall (Detail F15)

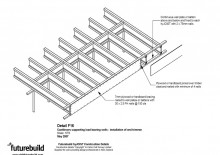

HYJ018 (F16)

Cantilevers supporting load-bearing walls - installation of end trimmer (Detail F16)

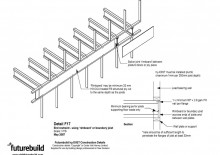

HYJ019 (F17)

End restraint - using rimboard or boundary joist (Detail F17)

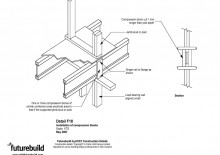

HYJ020 (F18)

Installation of compression blocks (Detail F18)

HYJ021 (F21)

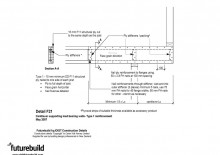

Cantilever supporting load-bearing walls- Type 1 reinforcement (Detail F21)

HYJ022 (F22)

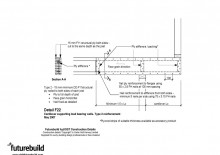

Cantilever supporting load-bearing walls- Type 2 reinforcement (Detail F22)

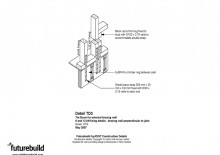

HYJ023 (TD1)

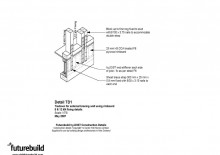

Tie-down for external bracing wall using rimboard using 6 12kN fixing detail (Detail TD1)

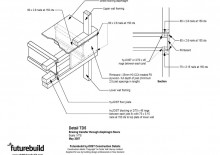

HYJ024 (TD2)

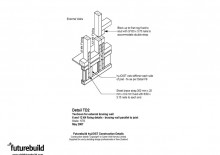

Tie-down for external bracing wall -6 and 12 kN fixing details - bracing wall parallel to joist (Detail TD2)

HYJ025 (TD3)

Tie-down for external bracing wall- 6 and 12 kN fixing details - bracing wall perpendicular to joist (Detail TD3)

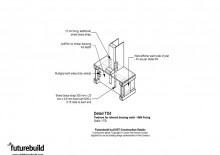

HYJ026 (TD4)

Tie-down for internal bracing walls - 6kN Fixing (Detail TD4)

HYJ027 (TD5)

Bracing transfer through diaphragm floors (Details TD5)

Information Bulletin

Lvl Beam Design Example Videos

Source: https://futurebuild.co.nz/products/hyspan/

Posted by: conleywaseve1964.blogspot.com

0 Response to "Lvl Beam Design Example Videos"

Post a Comment